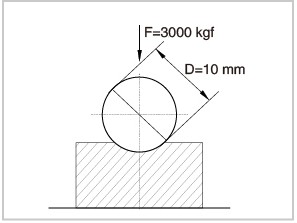

Install the testing head into the chain adaptor, when testing, using the chain to fix the tester on the surface of the work piece. And then handle the pressure lever to apply test force. The testing head is a small hydraulic system in which a release valve is used to control the test force. When the test force rises 3000kgf, the release valve will open and pressure will fall down, and it needs to apply the test force repeatedly 3-4 times to make the needle of the pressure gage point to 3000kgf for 3-4 times. Thus it is equivalent to the test condition of Brinell hardness testing method to hold 3000kgf test force with 10mm ball for 10-15 seconds, which complies with ASTM E110.

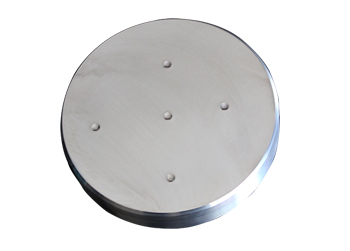

Technical Parameters of PHB-3000a Chain Hydraulic Brinell Hardness Tester

| Test Force: 3000kgf (1000kgf, 750kgf, 500kgf optional) Test Ball: 10mm Carbide alloy test ball (5mm optional) Test Range: 32-650HBW Test Diameter: ≤500mm Indicator Error: Complies with ISO 6506, and ASTM E10 Repeatability Error: Complies with ISO 6506, and ASTM E10 Test Force Error: ≤1% and Complies with ISO 6506, and ASTM E10 Weight: 14.5kg |

Relevant Standards of PHB-3000a Hydraulic Brinell Hardness Tester

ASTM Standards

ASTM E10-14 Standard Test Method for Brinell Hardness of Metallic Materials

International Standards

ISO 6506-2:2014 Metallic Materials- Brinell Hardness Test-Part 2: Verification and Calibration of Hardness Testing Machines.

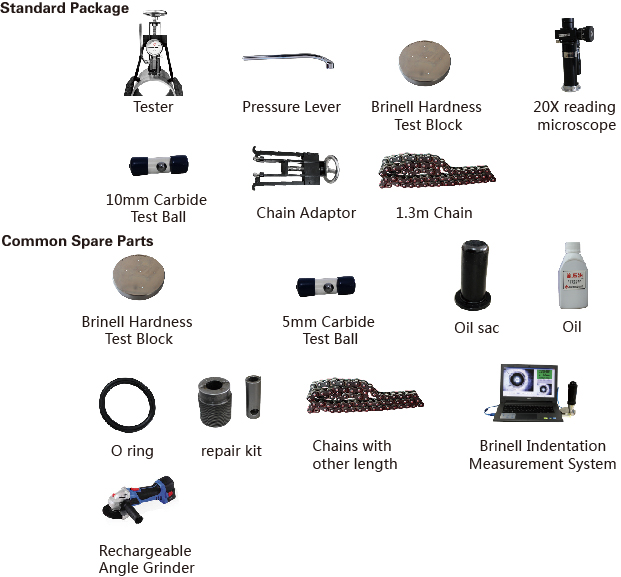

Package of PHB-3000a Hydraulic Brinell Hardness Tester

Model Selection