After more than 30 years of development, TX portable metal hardness tester has reached more than 50 models of products. Its main products are widely used in petroluem, electric power, metallurgy, machining, heat treatment and other industries.

The portable hand-held metal hardness tester could be applied in workshop and sales on-site, simple operation, easy carrying, and testing body of hardness of work piece one by one.

Indication error, repeatability error and test force accuracy comply with ISO and ASTM standards, the same as bench type hardness testers.

We are one of the professional hardness tester manufacturers, and we can supply complete technical support and after-sales service and quick delivery after payment.

Magnetic series hardness testers are designed and manufactured by TX Company, with high-accuracy sensor and unique distance measuring technology, reaching far higher test accuracy than other portable hardness testers.

Portable Brinell hardness tester including brinell testing machine can be used in the field, directly test large and medium-sized workpiece body without sampling, can test those large, assembled, non-cutting or inconvenient to move workpiece. For example, this hand-held metal hardness tester is used in the workshop to test casting and forging blanks, finished steel and semi-finished workpieces after tempering and heat treatment.

Portable rockwell hardness tester for sale can be used like a micrometer. All kinds of small and medium-sized metal parts and too long, too heavy, inconvenient to move plates, belts, rods, tubes and other large workpieces can be tested as long as they can be placed in the instrument opening.

Portable hardness tester adopts the real Brinell hardness test principle, the same as the bench-type hardness tester. The test results by the portable hardness tester for sale are real and reliable, in line with ASTM E10, E18 and ISO6506, 6508 and other international standards.

Under the portable hardness tester there are portable Brinell, portable Rockwell, Leeb hardness tester, ultrasonic hardness tester and so on. The main research and development and production of Shenyang TX Testing Instruments Inc. are portable Brinell and portable Rockwell hardness tester. Therefore, the Portable Hardness Tester Working Principle will be divided into Portable Rockwell Hardness Tester Principle and Portable Brinell Hardness Tester.

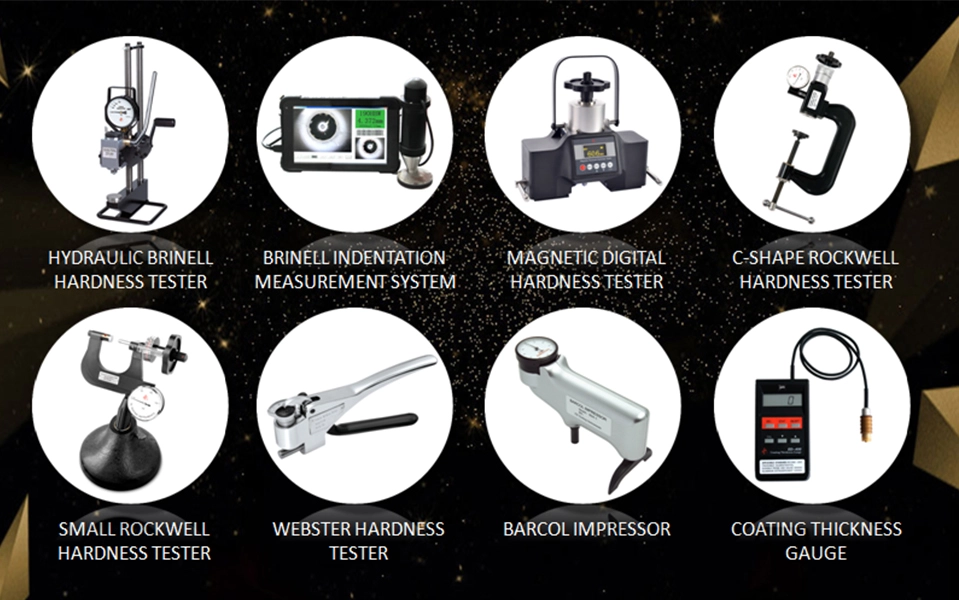

As illustrated in Fig. 1, the indenter is pressed (diamond cone or carbide ball ) into the specimen surface in two steps. After maintaining the pressure for a predetermined period of time, unload the major test force F1, and measure the remaining indentation depth h under initial test force F0.

Rockwell hardness value is:

In this equation:

N — a constant related to scales; for A, C, D, N and T scales, N=100; for B, E, F, G, H and V scales, N=130.

S — unit indentation depth, for Rockwell hardness it is 0.002mm, for superficial Rockwell hardness it is 0.001mm.

1 — indentation depth under initial test force F0;

2 — indentation depth under total test forces F0+F1;

3 — elastic recovery depth when major test force F1 is removed;

4 — remaining indentation depth h;

5 — test piece surface;

6 — datum plane;

7 — position of indenter

Rockwell hardness portable testers are designed according to the basic principle of Rockwell hardness test. The main differences from the bench-type lie in: the test force is applied by a screw and a calibrated U-shape spring; two indicators are installed on the tester: one indicating dial indicates the test force value by measuring the deformation of the elastomer and one precision screw micrometer used for testing the indentation depth; one barrel dial installed on the micrometer shows the hardness values. The principle and structure of this instrument is in accordance with the American Standard ASTM E110.

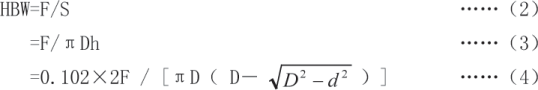

Apply a standard test force F to the carbide ball indenter with a diameter of D and press it into the specimen surface; keep on pressing for a set period of time, then remove the test force F and a round indentation with depth h is obtained on the surface of the test piece. Measure the indentation’s average diameter d, the Brinell hardness can be calculated by the quotient of test force divided by indentation’s surface area.