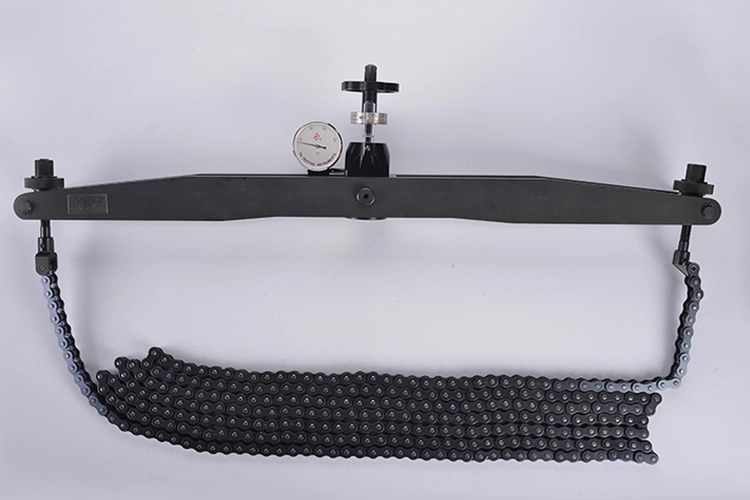

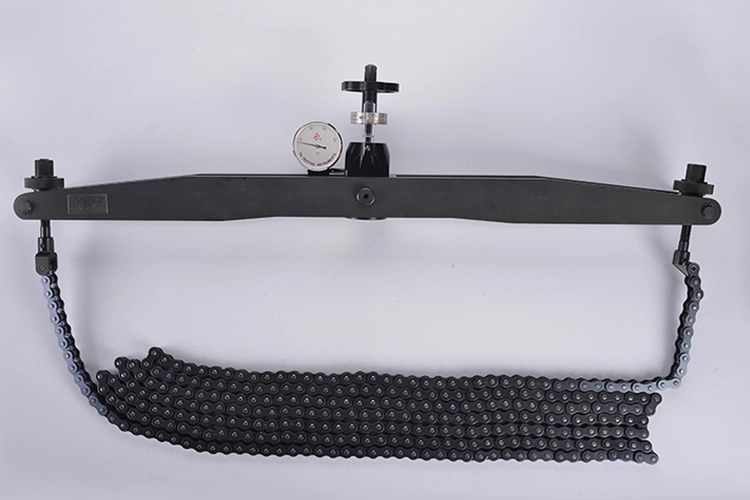

It is used in the field to accurately detect Rockwell hardness values of large and medium-sized steel pipes, gas cylinders, shaft, rollers etc., tests on the welding line; tests in segments. The hardness test can be completed by fixing the test head on the surface of the workpiece with a chain. Used for manufacturing inspection and acceptance inspection to replace Leeb hardness tester.

International Standard. The test principle and accuracy equivalent to bench hardness tester, comply to standard ISO6508 and ASTM E110.

Traceability. Traceable standard hardness block, test force calibrated with load cells directly traceable to national secondary benchmark.

Wide Testing Range. This type of rockwell hardness tester for sale is mainly used in pipe manufactory for accurately testing pipes of various sizes.

| PHR-16 / PHR-32 / PHR-64 | |

| Rockwell Initial Test Force | 10 kgf |

| Rockwell Total Test Force | 60 kgf, 100 kgf, 150kgf |

| Rockwell indenter | 120° Diamond Indenter 1/16" Carbide Ball Indenter |

| Accuracy | comply with ISO 6508 standards |

| Test Resolution | Rockwell:0.5 HR |

| Test Range | Rockwell: 20~70 HRC, 20~100 HRB, 20~88 HRA … etc.15 scales |

| Standard Assembly | Optional Accessories |

| Tester | 120° Diamond Indenter |

| 120° Diamond Indenter | 1/16", 1/8", Carbide Ball Indenter |

| 1/16" Carbide Ball Indenter | 1/4", 1/2", Steel Ball Indenter |

| 3 pcs Rockwell Hardness Block | Rockwell Hardness Block(HRC-high, HRC-low, HRB) |

| Flat Anvil | / |

| V Anvil | Wrench |

| Wrench | |

| Carrying Case |

| Model Selection | |||||

| Model | Specimen Size W X D (mm) | Net Weight (kg) | Gross Weight (kg) | Package Dimensions (mmxmmxmm) | Remarks |

| PHR-16 | 150~500 | 4.8 | 13.0 | 700*470*270 | The number in the model name indicates the maximum diameter of work piece can be tested. |

| PHR-32 | 300~1000 | 6.8 | 15.0 | 700*470*270 | |

| PHR-64 | 470~1400 | 11.5 | 23.0 | 1000*460*260 |