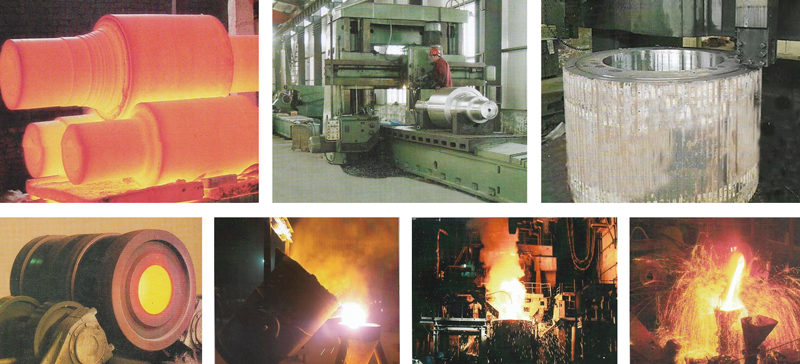

Heat treatment is a common metal material processing technology, through the process of heating and cooling metal materials can change its structure and performance, so as to achieve a certain hardness and strength requirements. The hardness test is one of the important means to evaluate whether the material meets the heat treatment standard.

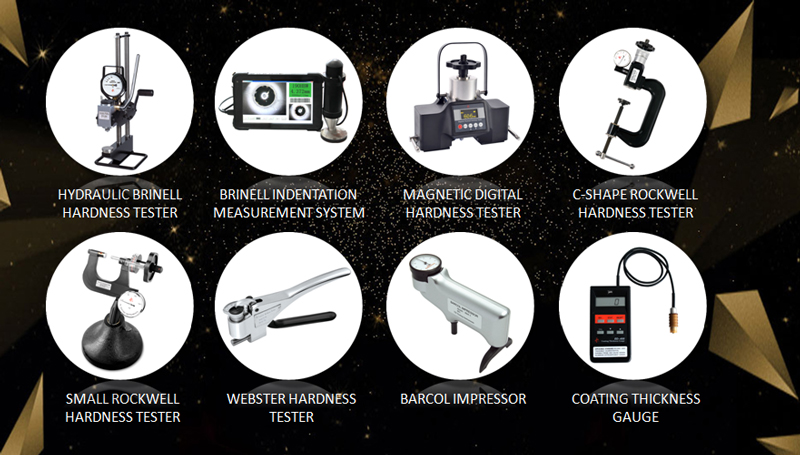

In the heat treatment process, hardness is an important parameter to measure the change of the internal structure of the material. The surface hardness test can evaluate the wear resistance, durability and fatigue resistance of the heat treated workpiece. The heat treatment process parameters can be optimized to provide a basis for subsequent heat treatment process adjustment and improve the quality and performance of heat treatment workpieces. For hardness testing of heat-treated parts, Vickers hardness tester, portable Brinell hardness tester and portable surface Rockwell hardness tester are usually used. Although the precision of the surface Rockwell hardness tester is not as high as the Vickers hardness tester, it has been able to meet the requirements as a testing means for quality management and qualification inspection of heat treatment plants. Moreover, it also has the characteristics of simple operation, convenient use, low price, rapid measurement, can directly read the hardness value, etc., the use of surface Rockwell hardness tester can be used for a batch of surface heat treatment workpiece for rapid and non-destructive piece by piece detection. This is important for metal processing and machinery manufacturing plants.