PHB-1 Pin impact Brinell hardness tester is designed following the Brinell hardness test method, loading test force by hammer impacting, force controlled by shear pin precisely. Test force F=1580 kgf, diameter of test ball D=7.26 mm, which leads F/D2=30. It follows Brinell similarity principle, equals to normal condition of 3,000 kgf, 10 mm test ball. It can be used to test the hardness of forgings, castings, steel products, and heat treatment parts, and also suitable for testing huge, super-huge parts those other instruments could not test.

Force Value Consistency. Good force value consistency, no influence by operator.

Easy Operation. Simple hit on side to test parts, low requirements on the shape and size of test piece.

High Reliability. Good repeatability and high accuracy. The Brinell hardness tester for sale could replace Leeb hardness tester in low accuracy and reliability.

Simple Operation. Only consume 1 piece of cheap shear pin for each test.

| PHB-1 | |

| Test Force | 1,580kgf |

| Indenter | 7.26 mm Steel Indenter, test range 100~350 HBW 4 mm Carbide Alloy Indenter, test range 350~650HBW |

| Indicator Error | ≤5% |

| Repeatability Error | ≤5% |

| Test Range | 100~650 HBW |

| Weight | 0.8 kg |

| Standard Assembly | Optional Accessories |

| 7.26mm Steel Indenter | 7.26mm Steel Indenter |

| Indenter Holder | 4mm Carbide Alloy Indenter |

| Impact Cylinder | Indenter Holder |

| Holding Handle | Impact Cylinder |

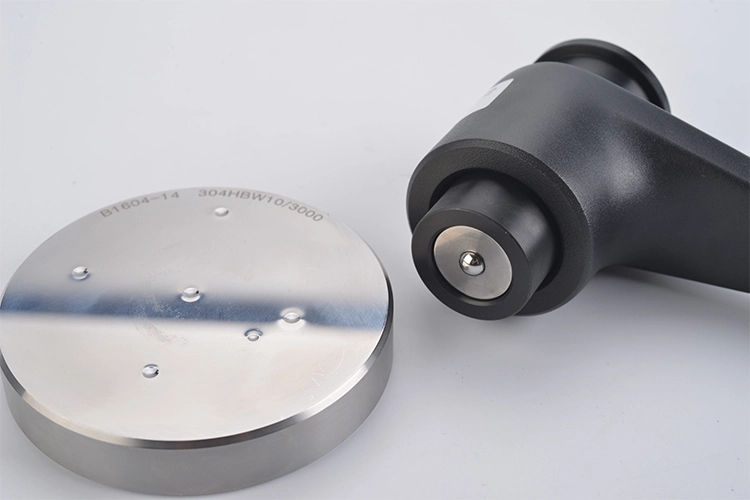

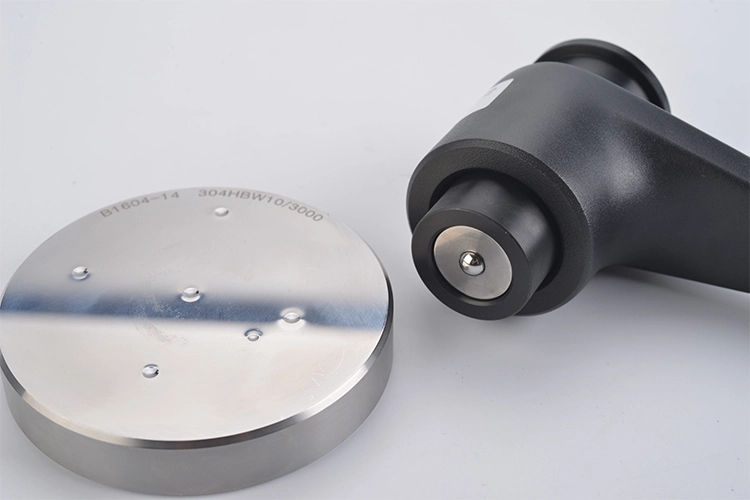

| Brinell Hardness Block(HB10/3000) | Pin (250 pieces/box) |

| Pin (250 pieces/box) | Brinell Hardness Block(HB10/3000) |

| Pin Removal Tool | 20x Reading Microscope |

| 20x Reading Microscope | 40x Reading Microscope |

| Carrying Case | Brinell Indentation Measurement System |