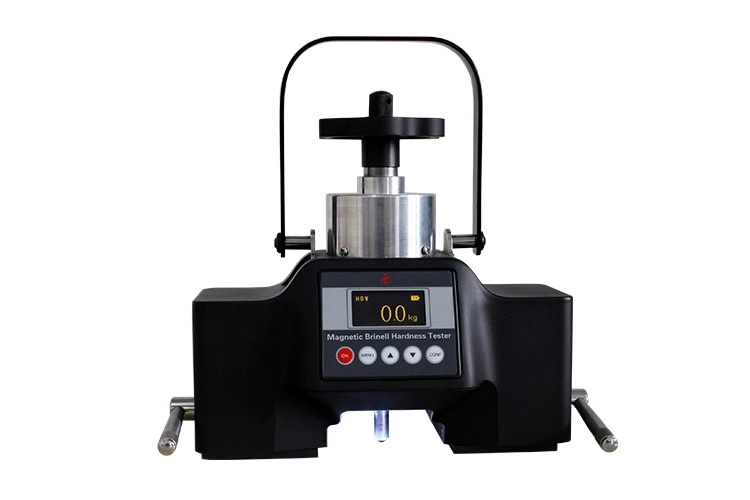

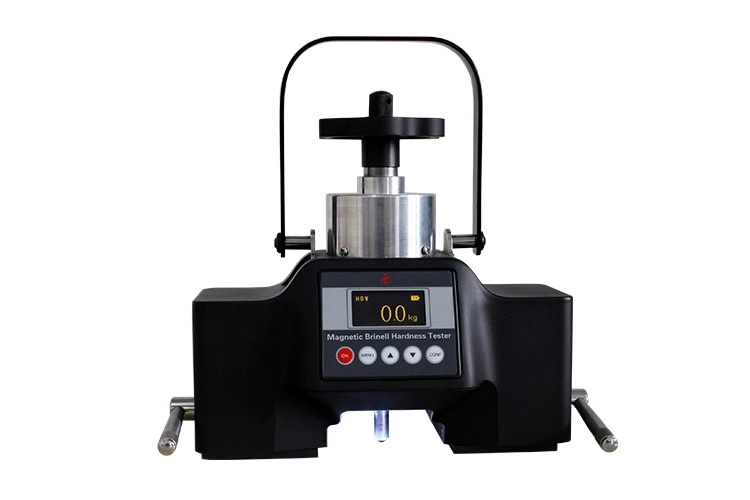

PHB-200 Magnetic Brinell hardness tester adopts Brinell hardness tester method, and test conditions meet the requirement of standards ASTM E110 and ISO 6506, it designed for rapid and accurate Brinell hardness test in the field, in combination with the MS-1 Brinell indentation measurements system. It can be used for large or heavy steel parts that cannot be tested with bench hardness testers, and also suitable for the steel plates, steel pipes, moulds, dies and other heat treated parts, as well as for testing on welding lines of boilers, pressure vessels and pressure pipes.

Patented Product. This Brinell hardness test equipment is the patented product of TX company, and is unique all over the world.

Small and Convenient. The tester has a weight of only 5.1kg, being the smallest Brinell Hardness Tester so far.

High Reliability. The PHB-200 Brinell hardness tester applies the abroad high qualified force sensor and electronic devices with high integration level and stability.

Design of Light. Bright and clear view at lighted test point brings much convenience for observing test procedure.

| PHB-200 | |

| Test Force | 187.5 kgf |

| Test Force Tolerance | ≤ ± 1%, comply with ISO and ASTM standards |

| Indenter | 2.5 mm carbide ball |

| Range of Testing | 100 ~ 650 HBW |

| Indicator Error | comply with ISO 6506, ASTM E110 |

| Repeatability Error | comply with ISO 6506, ASTM E110 |

| Working Temperature | 5~45 ℃ |

| Dimensions | 245mm x 105mm x 238mm |

| Weight | 5.1 kg |

| Minimum Testing Surface | Flat: Area ≥195mm x 60mm Thickness≥ 5mm |

| Cylinder: Diameter≥50mm, Length≥200mm, Thickness≥ 8mm |

| Standard Assembly | Optional Accessories |

| Tester | Brinell hardness block(high or low value) |

| 40x Reading Microscope | 2.5mm Carbide ball |

| Iron Seat / Base | Brinell Indentation Measurement System |

| 2.5mm Carbide Ball Indenter | |

| Brinell hardness block | |

| Battery Holder | |

| Carrying Case |