PHR-300 Automatic Magnetic Rockwell hardness tester applies traditional Rockwell hardness test method same with table hardness tester. Test procedure and accuracy are all in accord with ASTM and ISO standard. This hardness tester applies a magnetic sucking disc to fix itself on test position of large steel work piece. An accurate and reliable measurement result can be obtained by one key operation. It applied in different shaped steel materials such as tube, pipe fitting, bar, plate and in large heat treatment parts such as large shaft and mould.

Updated Structural Design. The hardness tester structure design is compact and reasonable, compared with PHR-200 digital magnetic hardness tester, PHR-300 has smaller size and close weight.

Simple Operation. Turn on the magnetic switch, and fix the hardness tester on work piece, all test procedure can be automatically made via one key operation and a test result is got, and in good stability.

High Accuracy. High accuracy force transducer, advanced closed loop measurement and control motor loading technology are applied to make sure accurate and reliable test force value and good uniformity.

| PHR-300 | |

| Initial Test Force | 10 kgf |

| Total Test Force | 60 kgf, 100 kgf, 150kgf |

| Test Cycle Duration | 15 s |

| Battery Life | around 400 times |

| Test Range | 20~70 HRC, 20~100 HRB, 20~88 HRA |

| Test Resolution | 0.1 HR |

| Indicator Error | comply with ISO 6508, ASTM E18, ASTM E110 |

| Repeatability Error | comply with ISO 6508, ASTM E18, ASTM E110 |

| Test Force Error | ± 1% |

| Test Force Fluctuation | 0.2 kgf |

| Working Temperature | 0~50 ℃ |

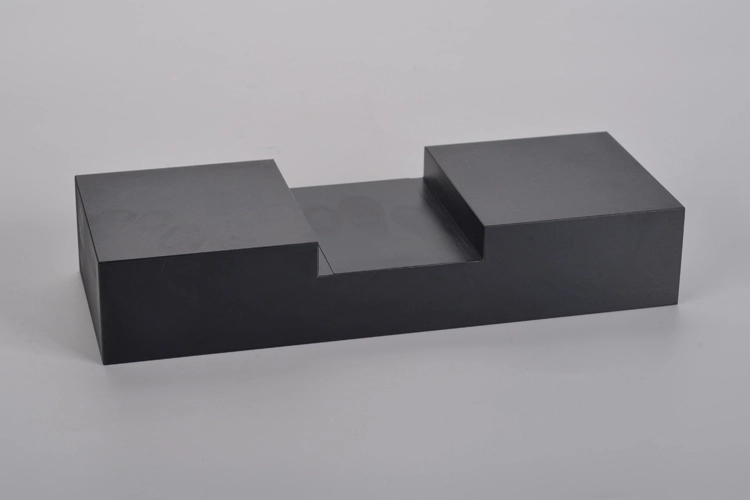

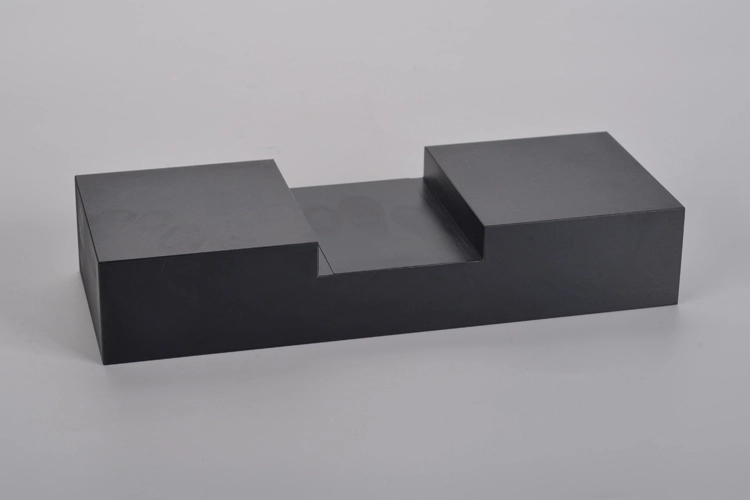

| Dimensions | 243mm x 105mm x 215mm |

| Weight | 5.1 kg |

| Minimum Testing Surface | Flat: 195mm x 60mm x 5mm (Length*Width*Thickness) |

| Cylinder: 60mm x 200mm x 8mm (Diameter*Length*Thickness) |

| Standard Assembly |

| Tester |

| Iron Seat / Base |

| Cylindrical Adaptor |

| 120° Diamond Indenter |

| 1/16" Carbide Ball Indenter |

| Rockwell Hardness Block |

| Carrying Case |