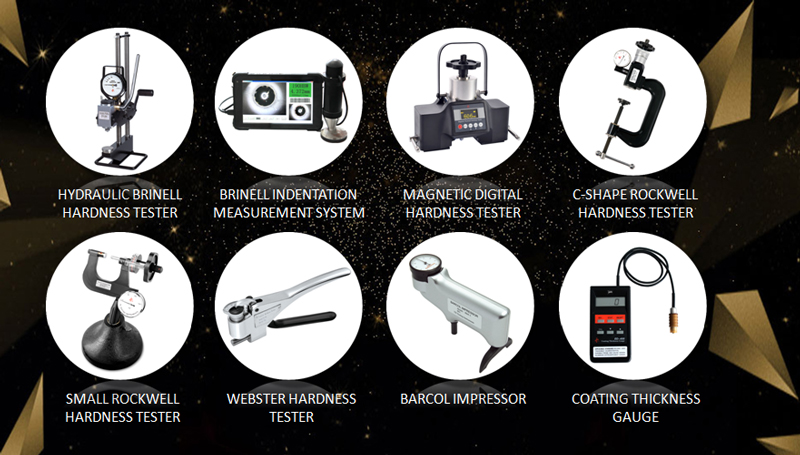

Hardness testing of building materials is a common quality control method. With the continuous increase of projects, the competition of construction enterprises is becoming more and more intense which makes the market environment of building materials industry more and more complicated, and the types of building materials are also increasing. How to do a good job in building materials testing has become an important prerequisite to ensure the construction quality of building projects. Therefore, it is of great significance to strengthen the application of modern detection technology for building materials, which will promote the development of building industry. The detection and evaluation of material strength is the basic requirement of on-site detection of building structures. Hardness measurement is a main index to test the properties of materials, and it is a quick and quick test method. In the testing of mechanical properties of materials, hardness testing is a simple, efficient and easy-to-implement testing method, which is the main means to determine the processing technology of materials and test the quality of products. For the tested material, hardness represents the comprehensive properties of elasticity, plasticity, strength, toughness and wear resistance reflected under a certain pressure head and test force. Hardness test can reflect the differences of metal materials under different chemical composition, microstructure and heat treatment process, so portable Brinell hardness tester and portable Rockwell hardness tester are widely used to test metal properties, supervise the quality of heat treatment process and develop new materials.

In industrial production, hardness tester, as an important testing tool, is widely used in testing and quality control of various materials and parts. Hardness is one of the important indexes to measure the strength and wear resistance of materials. Rubber is a commonly used material in food, medicine, medical equipment, automobile parts and other industries. The Barcol hardness tester model 935 is widely used in the hardness testing field of rubber and other materials, which can be used to test the hardness of rubber and ensure the quality and performance of rubber products. For the hardness testing of plastics and rubber, the commonly used methods include Barcol hardness and so on. Barcol hardness tester model 935 is a special instrument for measuring rubber hardness, which determines the hardness of materials by measuring the depth of indentation on the surface of materials. Barcol hardness tester model 935 is suitable for rubber materials with different hardness. To sum up, hardness tester plays an important role and application value in the detection and quality control of various materials and parts. For different types and uses of materials and parts, it is necessary to select appropriate hardness tester for testing to ensure the improvement of product quality and production efficiency.