Rockwell hardness testing is widely used in batch testing on production site because of its simple operation and small indentation. There are three kinds of Rockwell hardness test forces, three kinds of indenters (62.5kgf, 125kgf, 187.5kgf test force; 1.588mm, 2.5mm and 5mm carbide ball indenters) are combined to have nine kinds of scales. The application of these nine scales covers almost all commonly used metal materials. The most commonly used scales are HRC, HRB and HRA. Among them, HRC scale is used to test quenched steel, tempered steel, and some stainless steel. This is the most widely used hardness test method in the metal processing industry. However, the Rockwell hardness testing of large and medium-sized steel pipe or shaft products has been a problem until the emergence of chain Rockwell hardness tester solves this problem.

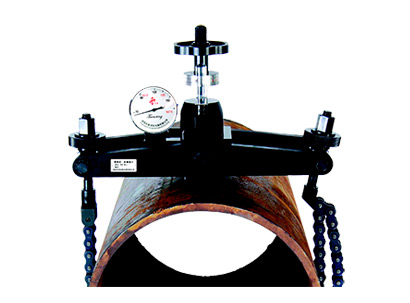

The chain Rockwell hardness tester uses the chain to fix the measuring head on the workpiece surface to complete the hardness test. The test principle and accuracy fully meet the relevant international standards, and the test accuracy can reach the level of table machine. It is suitable for the on-site Rockwell hardness test of large and medium-sized steel pipes or shafts. There are three types of chain Rockwell hardness tester. The diameter range of workpiece measured by PHR-16 is 200 ~ 450mm, the diameter range of workpiece measured by PHR-32 is 400 ~ 850mm, and the diameter range of workpiece measured by PHR-64 is 800 ~ 1600mm.