Impact Brinell hardness tester is showed in Figure 1. The tester is a small simple device, with a spring, and a spring compression and release structure installed in it. On the top, there is a steel ball. While testing, press down the device slowly, then the spring would be compressed, and then be released. The impacting force would make the steel ball press into the surface of specimen, with an indentation left on it. Measure the diameter of indentation by using a reading microscope, then get the Brinell hardness value after looking up the conversion table.

This kind of tester has a simple structure, easy operation, and cheap price. However, the test force is uncertain, and the error is high, with test resolution of ±8%. The testers could just be applied in the situation in which there is no quite high requirement for test resolution. As the technique of this kind of instrument is too old, the stabillity is not as good as Brinell hardness tester, it is used less than others in producing site.

Figure 1. Impact Brinell Hardness Tester Figure 2. Hammer Impact Brinell Hardness Tester

Hammer impact Brinell hardness tester is showed in Figure 2. The tester is made of support, steel ball, bar hardness block, and reading microscope. While testing, use a hammer to hit the top of the support, the impact force of the steel ball would force on specimen and hardness block, leaving an indentation on the specimen and hardness block. There is certain proportional relation between the two indentations, and measure the indentaion diameter seperately, look up conversion table, get Brinell hardness value. This test method is stipulated in the American standard ASTM A883, and the calibration method is stipulated in the national metrology verification regulation JJG870-1994.

This kind of instrument has a simple structure, easy operation, and cheap price. However, the test force is uncertain, and the error is high, with test resolution of ±8%. The instrument could just be applied in the situation in which there is no quite high requirement for test resolution. So far, the tester has been widely used on site in domestic casting, forging, rolled steel, and heat treatment industries.

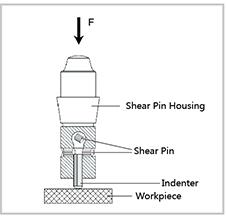

Figure 3a. Pin Impact Brinell Hardness Tester

Figure 3b. Working Principle of Pin Impact Brinell Hardness Tester

The pin impact Brinell hardness tester is showed in Figure 3a, and the structure is showed in 3b. The tester is made of shear pin housing, shear pin, ball indenter, housing, and handle. While testing, install the shear pin and indenter in shear pin housing, and put the shear pin housing in housing, and put the housing in the handle. Then put the whole part on specimen. Use a hammer to hit the top of shear pin housing, and test force would pass into indenter through the pin. The ball shape surface of the indenter will be pressed into specimen, leaving an indentation on it. When the impact force reaches the rated shearing force 1580kg of shear pin, the pin would be cut off by the cutting system which is made of shear pin house and indenter momently. Then the test force disappears, and the actual test force is just 1580kg. Measure the diameter of the indentation, look up the conversion table, and get the Brinell hardness value.

The pin impact Brinell hardness tester complies with the similarity principle of Brinell hardness testing. The test force of tester is 1580kg, the diameter of the ball indenter is 7.26mm, so F/D2 is 30. The test condition is equivalent to 3000kgf test force and 10mm ball indenter.

The static pin impact Brinell hardness tester is showed in the following picture.

Figure 3c. Static Pin Impact Brinell Hardness Tester

The pin impact Brinell hardness tester has simple structure, easy operation, high reliability, and more similar test principle with Brinell hardness testing principle. With accurate test force, excellent repeatibility, and high accuracy, the hammer impact force loading has a little error less than ±5% while the static impact force loading has a error less than ±3%. This kind of tester is widely applied in European countries and America. So far, the tester has been produced in China.