The Pin Impact Brinell hardness tester is composed of the test head, impact cylinder, holding handle and hammer.

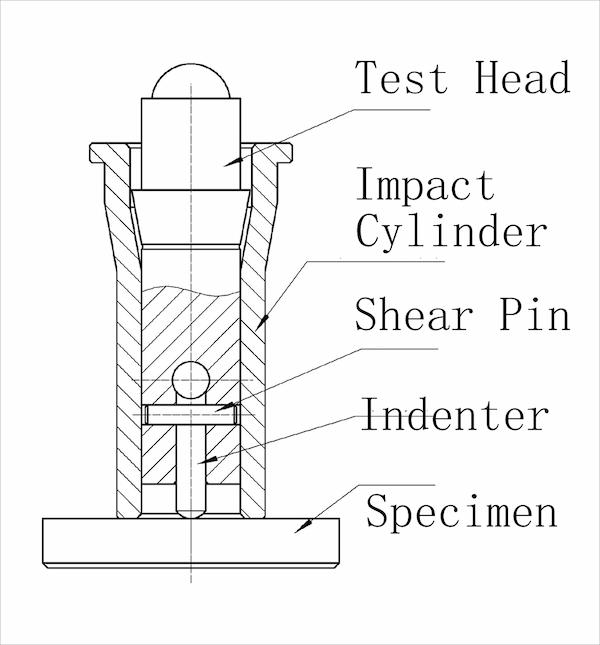

The principle of the instrument and inside structure of the test head are shown in Fig.4.

Fig. 4 Principle of the instrument

A shear pin is place in the horizontal hole on the test head. The indenter is pushed into the bottom hole and its top touches shear pin. The test head is placed into the impact cylinder.

When the test force is applied on top of the test head, the force is transmitted to the indenter through the shear pin which presses indenter against the specimen. As soon as the test force reaches 1580kg, the shear pin is cut into three segments by the cutting system comprising the test head and the indenter. The excessive force will not be transmitted to the indenter as it withdraws into bottom hole of the test head,and a round indentation will remain on the surface of the specimen.

The indentation diameter is measured with a reading microscope, and the Brinell hardness number can be obtained from the lookup table.