Small diameter pipe is widely used in industrial production. How to conveniently prepare and efficiently detect the hardness of small diameter pipe on the production site is an important link to improve the quality of small diameter pipe. In the past, the hardness of small-diameter pipes was mostly tested by Leeb hardness tester, but the Leeb hardness deviation value is very large. With the more and more strict requirements for the quality of pipe fittings, the Leeb hardness has become more and more inconsistent with the requirements for high-quality pipe fittings. Selecting a suitable Rockwell or Brinell hardness tester is undoubtedly an urgent problem for manufacturers.

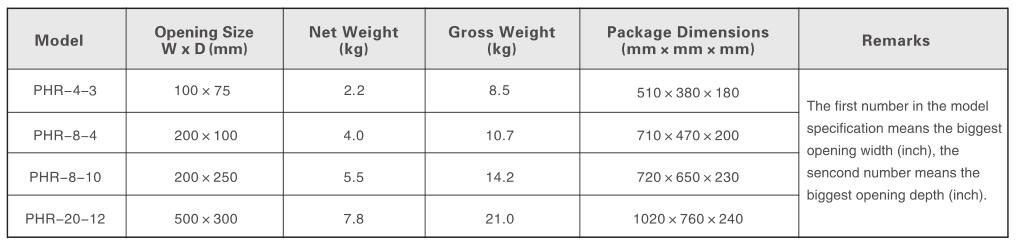

The PHBR series C-type broach hardness tester produced by our company is especially suitable for on-site broach hardness measurement of small diameter. This series of broach hardness tester is composed of C-type frame, screw and hardness probe. Bullock or single Rockwell models can be selected, and there are 8 sizes to adapt to different sizes of small-diameter pipes. The specific sizes are shown in the tables below:

This series adopts the reading mechanism like micrometer, which is accurate, convenient and repeatable. It can replace the Leeb hardness tester with low measurement accuracy in the field of industrial production.