The PHBR-200 digital magnetic Brinell & Rockwell hardness tester independently developed by Shenyang TX has won patents from many countries. It has simple operation and high precision of test results. It has been widely used in the production sites of electric power, special inspection, pressure vessels, large forging and casting industries for the rapid detection of Rockwell or Brinell hardness on site. The following describes the important components of this instrument, so that users can be more handy in the process of use.

This instrument is equipped with a universal adapter when leaving the factory. The universal adapter can test flat and cylindrical workpieces. If you need to measure workpieces with special shapes, you can contact our company. Our company can customize other adapters for you according to the actual situation.

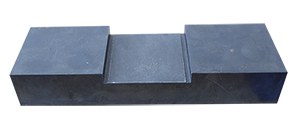

The base iron in the instrument box is made of high magnetic conductivity material, which is used to measure small workpieces or hardness blocks during instrument calibration. The base iron is easy to rust. Pay attention to timely cleaning and keeping it dry during use and storage.

The hardness blocks delivered by our company are calibrated by a traceable standard machine, and the shelf life is 2 years. Please use the hardness blocks within the shelf life, so as to ensure the correction results of hardness values.

This instrument will produce strong magnetism during use to ensure the accuracy of test force loading, so the correct use of magnetic switch is related to the accuracy of test results. Before the instrument is in the measuring state, please turn the magnetic switch to the on position and ensure that the handle of the magnetic switch is horizontal. During the use of the instrument, please keep the mobile phone, headset and other electronic products away from the instrument to avoid damage to it by strong magnetic field.